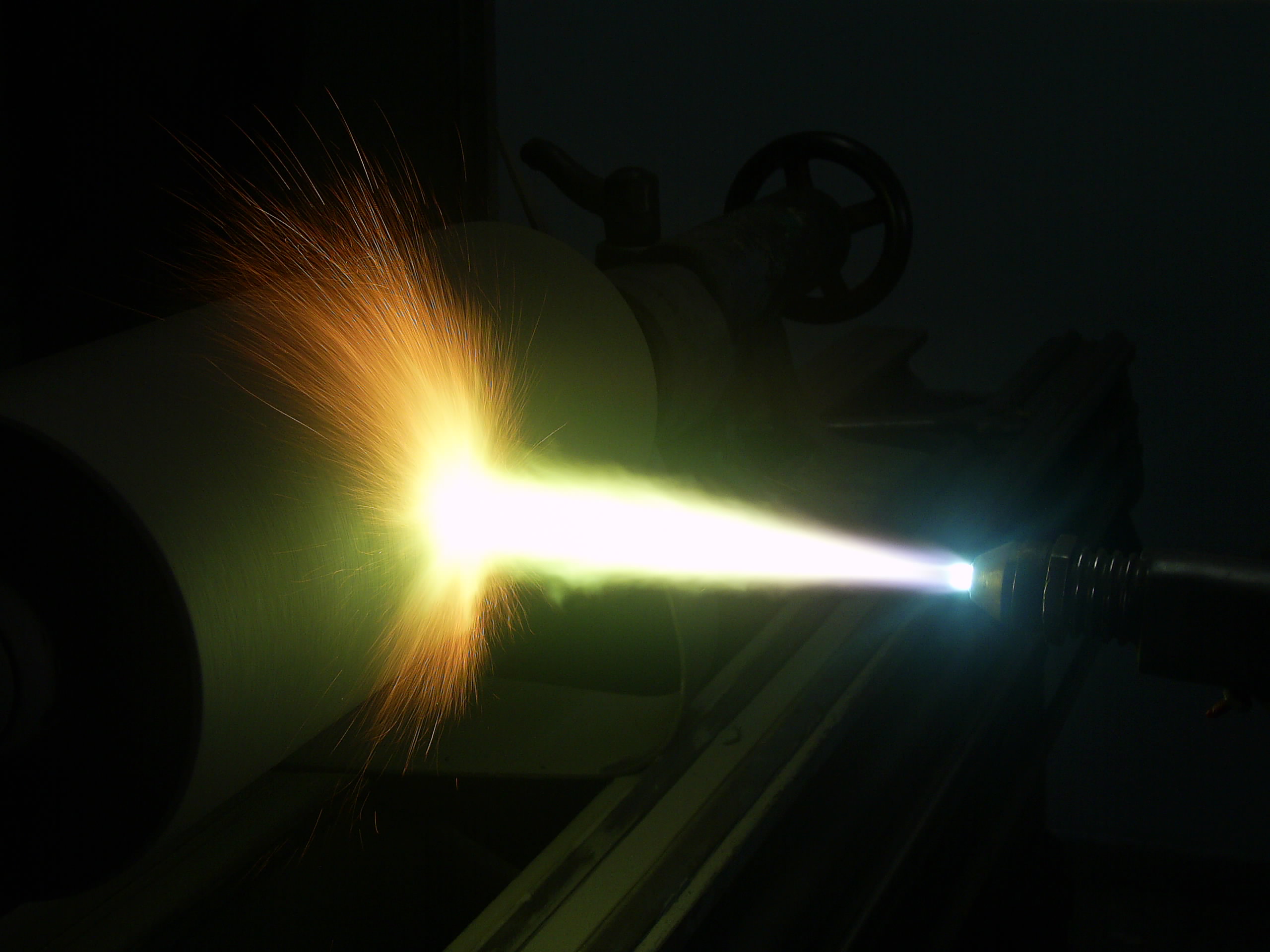

Powder flame method coatings made with various metal powders (Nickel, Cobalt and Tungsten Carbide) and ceramic powders of various alloys (Chromoxide, Aluminum Oxide, Zirconium Oxide) are used to obtain fillings for repair purposes and coatings that can work at high temperatures resistant to abrasion, cavitation, corrosion, metal-to-metal friction.

POWDER ALLOYS USED

Stainless Steels, Carbon Steels, Nickel Chromium Alloys, Tungsten Carbide Cobalt Alloys, Bronzes, Ceramic-Metal mixtures.

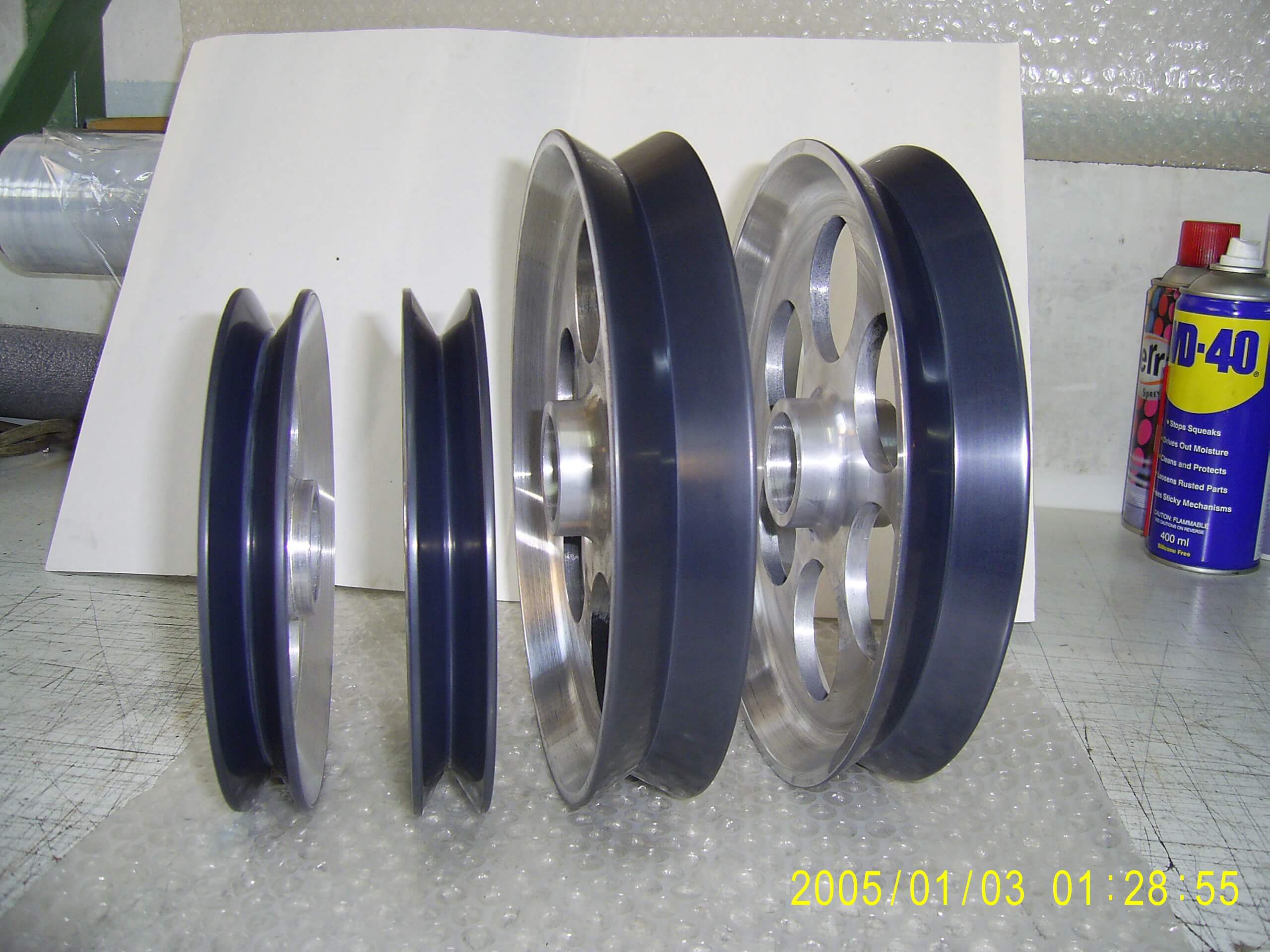

APPLICATION AREAS

Bearing Locations, Shaft Trunnions, Compressor Pistons, Cam Shafts, Bushings and Sleeves, Hydraulic Cylinder Pistons.

Glass Industry; Moulds, Masters

Wire Drawing Industry; Wire Drawing Rollers

Iron and Steel Industry; Rolls, Guide Rolls

Petro-Chemical Industry; Piston rods, Shaft Protective Bushes

Brick Industry; Compression and Transport Coils